Advance Analytical

เครื่องมือวิเคราะห์ทางวิทยาศาสตร์ขั้นสูง Advance Analytical

- Dynamic Beam Optimization – no instrument reconfiguration by operator needed

- LYNXEYE XE-T detector – highest data quality and lowest quantification limits

- TouchControl – intuitive touch-screen operation, operator training almost unnecessary

- ECO version – 1 kW for low running costs by energy savings and no need for cooling water

- Harsh environment, high altitude option – highest reliability at all environmental conditions

The system is well suited for multi-user operation in industry, academia and research. For industrial process optimization and quality control, the D8 ENDEAVOR can be interfaced to an automated sample preparation system, which feeds the samples via a conveyor belt or robot.

Turn-key versions of the D8 ENDEAVOR are available for the Cement, Minerals, Pharma, Aluminum, and Metals industries. They include:

- specific instrument configurations,

- optimized data acquisition and evaluation packages,

- industry specific application training and support.

D8 ENDEAVOR - Ready-to-use and capable of any level of automation.

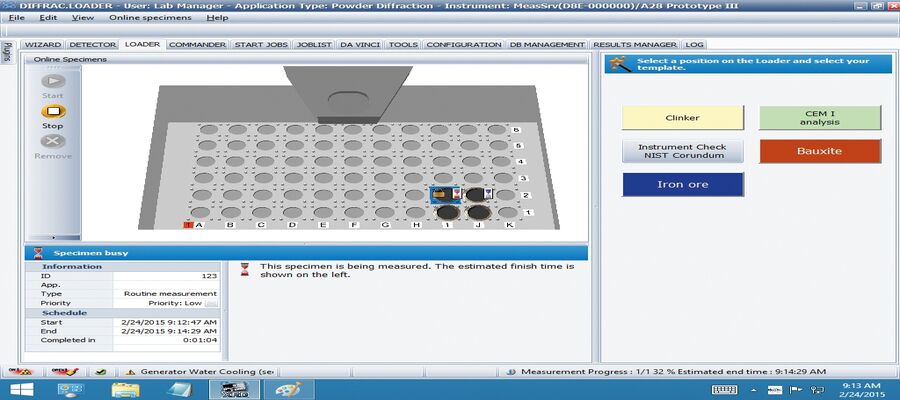

Sample handling with the D8 ENDEAVOR

Fine grained powder is filled into sample holder cavities of various diameter or depth matching the sample amount.

Back-loading is available to reduce preferred orientation.

Very small amounts of powder can be prepared on background-free holders.

Specialized holders for filters, clays, solids, and environmentally sensitive samples are further options of a broad choice.

D8 ENDEAVOR Cement

Combined with the XRD Method Package Cement the new D8 ENDEAVOR is the perfect solution for the industry.

It offers direct phase analysis along the entire production process, ranging from raw materials, intermediate products like hotmeal and dusts (REACH) to clinker and the finalized cements. Analytical highlights are the capability to distinguish the Alite polymorphs M1 & M3 and the quantification of amorphous phases by the proprietary PONKCS method.

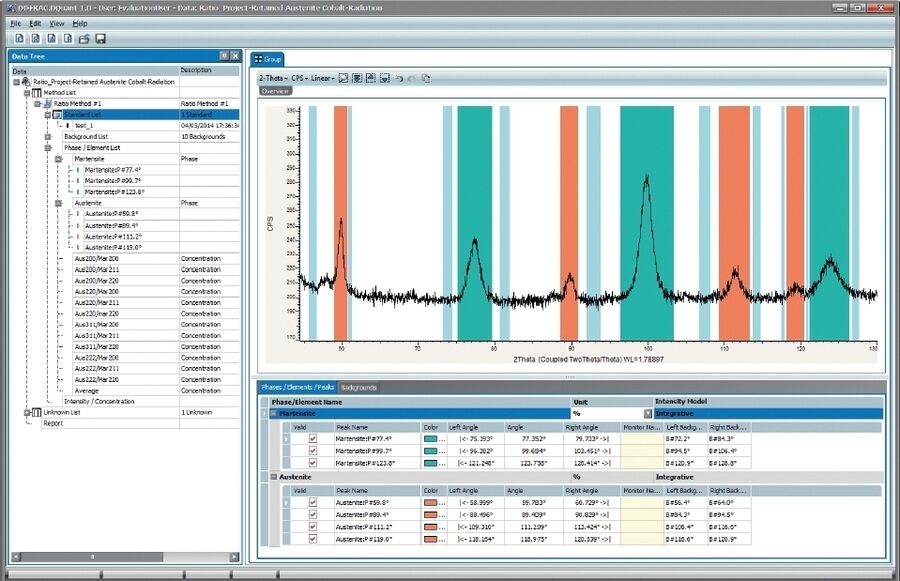

D8 ENDEAVOR Metals

Knowing the exact FeO concentration in the raw material is key to cut the greenhouse-gas emission of iron plants.

The FeO amount can directly be calculated from the stoichiometry and concentration of the minerals. These values determined by rapid XRD makes it a very fast alternative to titration.

Respirable Silica

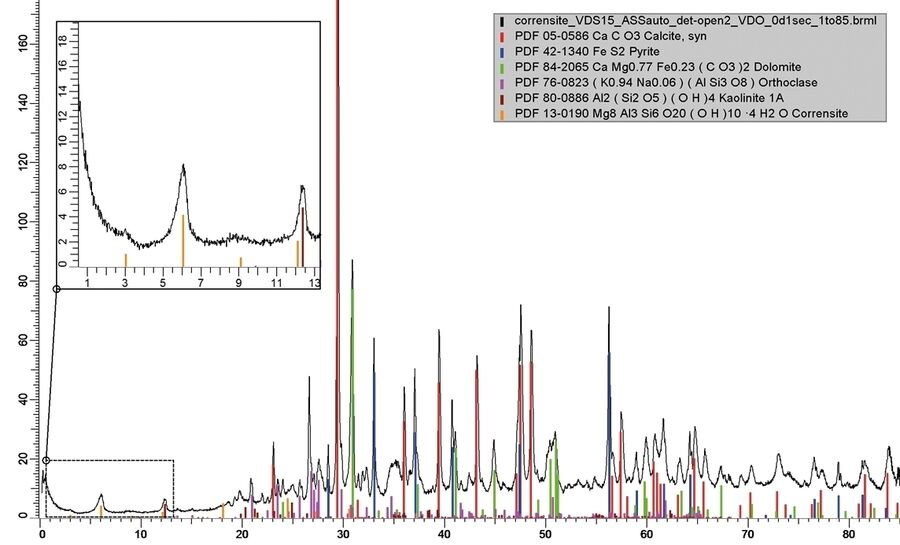

D8 ENDEAVOR Minerals

Complex geologic materials can reliably be analyzed using TOPAS quantitative analysis.

Furthermore, cluster analysis techniques can be used to quickly and automatically analyze large amounts of data for similarities and generate exploration mappings.

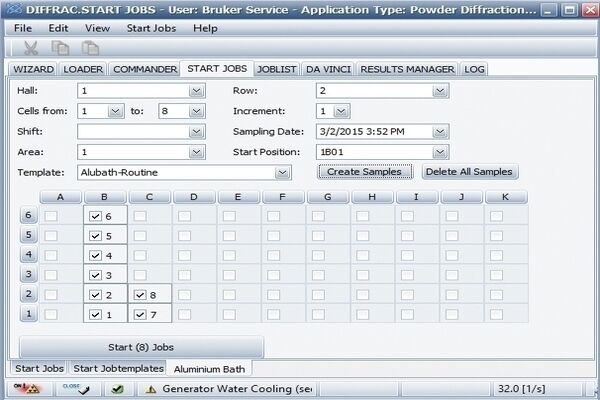

D8 ENDEAVOR Aluminum

Firstly, due to the harsh environment in a smelter, where the XRD instrument needs to be located.

And secondly, due to the enormous sample throughput required to successively probe hundreds of smelter cells permanently. The D8 ENDEAVOR addresses these challenges with technological innovations reducing measurement times and expanding analysis capabilities.

Contact us

388/5 Nuanchan Road, Nuanchan,

Buengkum, Bangkok 10230

0 2363 8585 (auto)

0 2363 8595

081 498 9939